Spiral Water‑Tight Zipper for Hiking Packs | YGZIP Waterproof Zipper

Explore YGZIP’s spiral water‑tight zipper designed for hiking packs—offering superior waterproof sealing, flexibility, and durability in outdoor conditions. Ideal for backpacks, tents, and gear.

Additional information

| Slider | |

|---|---|

| Feature | |

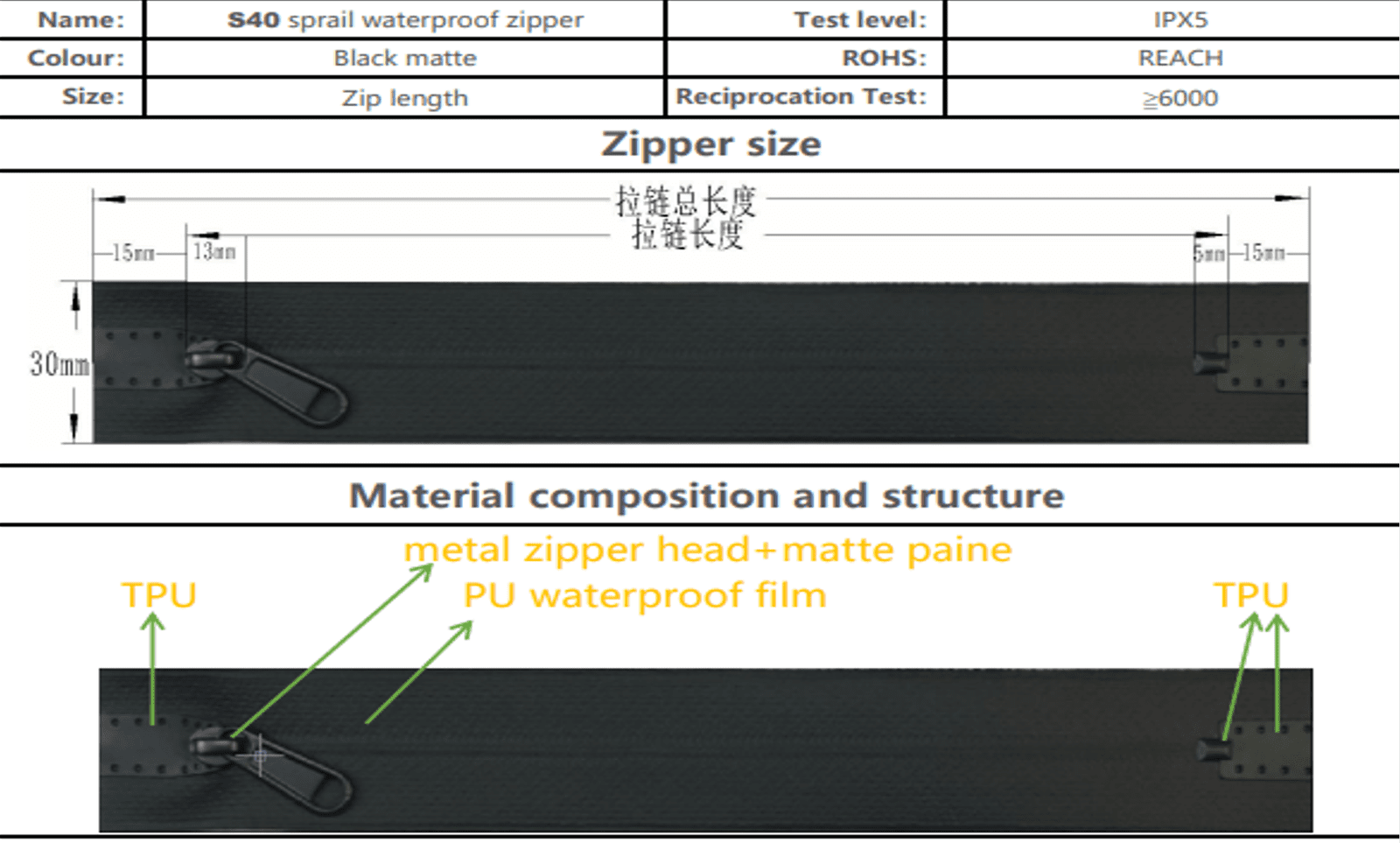

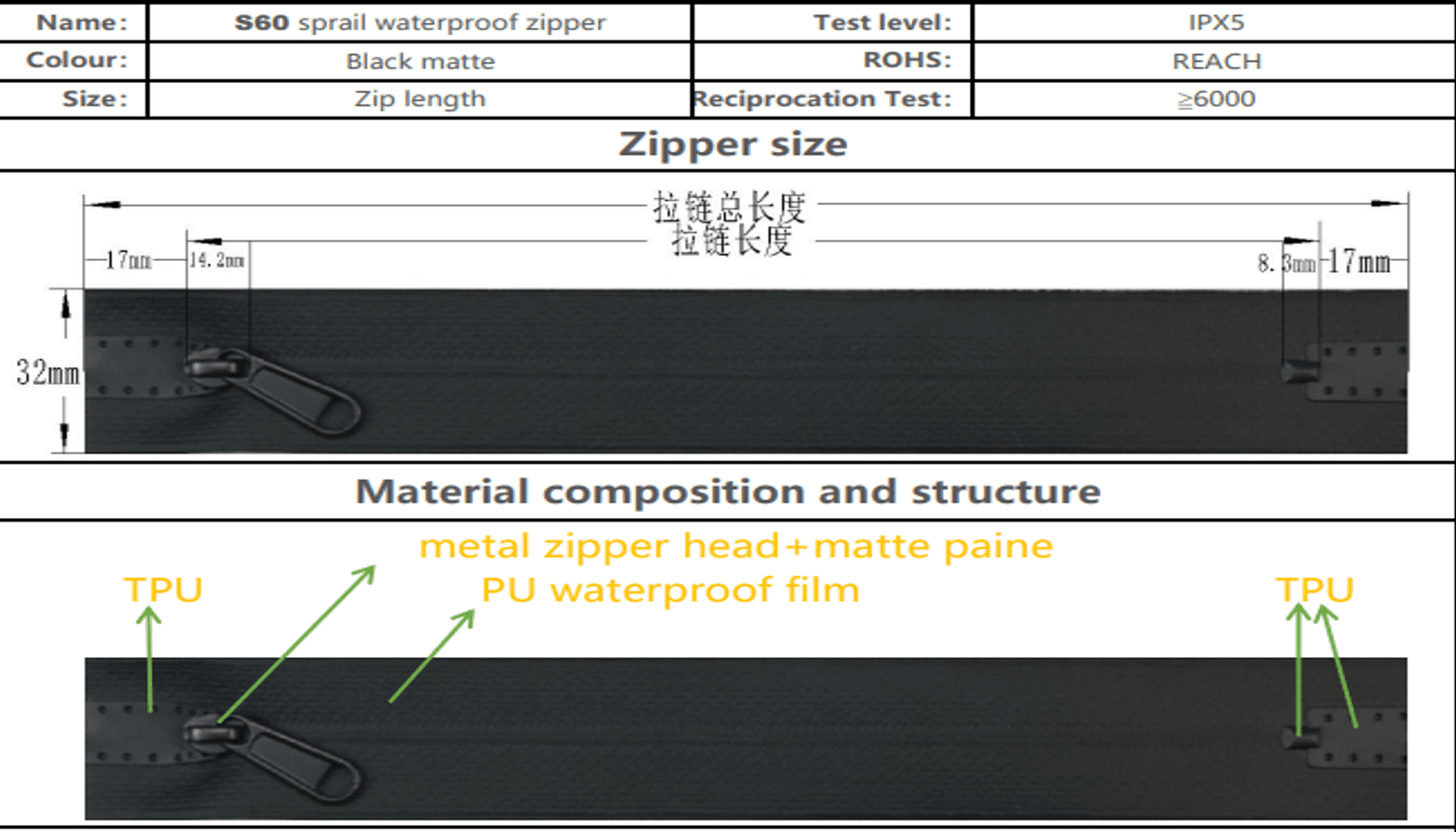

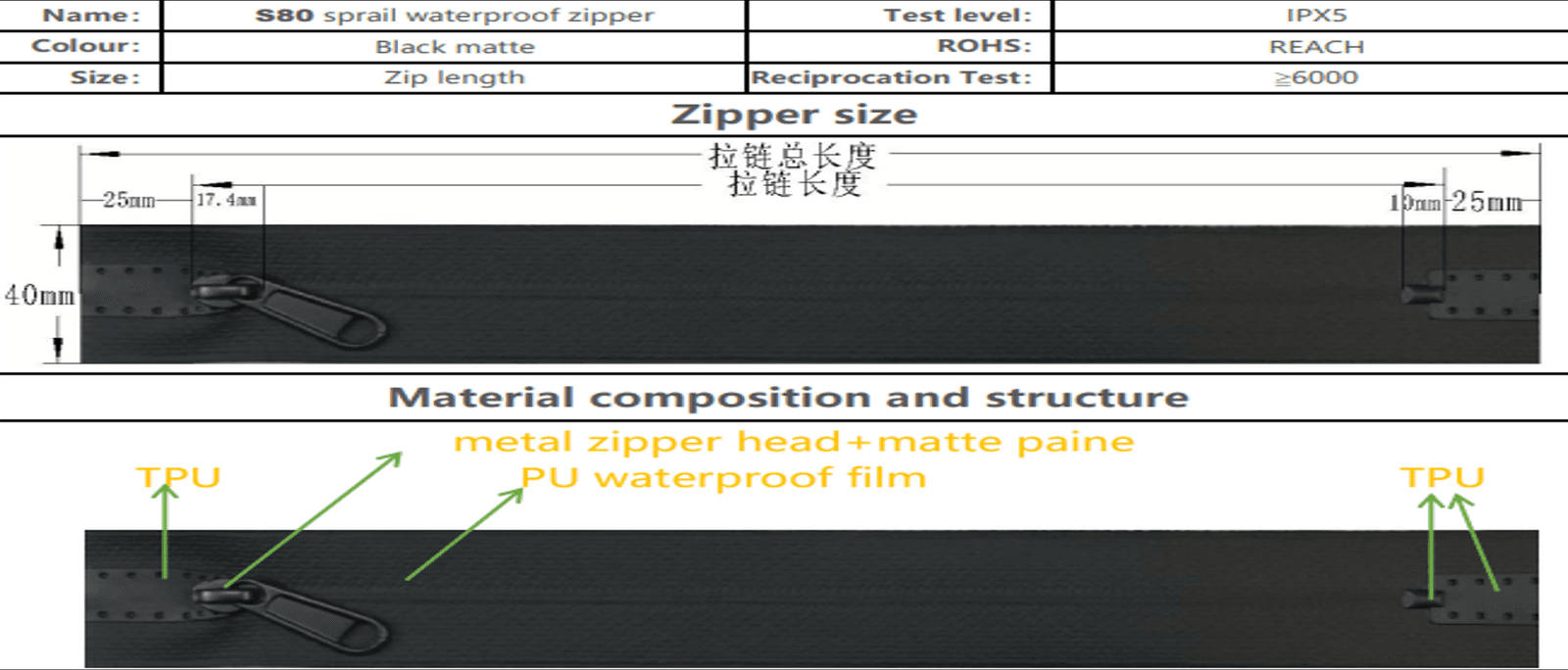

| Size | S40, S60, S80 |

| Color | Black, Customized pantone color, White |

| Material | |

| Application |

The manufacturing process of the product

Production Process of Spiral Water-tight Zipper

- Raw Material Preparation:

- Made from high-strength nylon or polyester spiral coil structure, offering flexibility, durability, and abrasion resistance — commonly used in outdoor gear and rugged equipment

- Prepare TPU (thermoplastic polyurethane) or rubber-based waterproof coatings for water-tight sealing.

- Auxiliary materials: Metal/plastic sliders, top/bottom stops, and polyester tape substrate.

- Nylon Braiding Process:

- Braid nylon yarn into continuous zipper teeth strips using high-speed braiding machines, controlling tooth spacing and density.

- Stabilize the shape through high-temperature heat pressing to prevent deformation.

- Coating and Sealing Treatment:

- Apply TPU or rubber coating evenly on the braided nylon tape to fill gaps between teeth.

- Cure the coating via UV or hot-air drying to form a seamless airtight layer.

- For premium products, add sealing strips at the tooth base for enhanced airtightness.

- Tape and Slider Assembly:

- Stitch the coated nylon braided teeth to polyester substrate tape for strength and flexibility.

- Assemble sliders with precision machinery to ensure smooth operation.

- Attach waterproof metal/plastic top/bottom stops to secure the slider.

- Water-tightness Testing & Quality Control:

- Water-tight Test: Mount the zipper on a test mold, inject compressed air (e.g., 0.5-1.0 bar), and measure leakage rate (≤0.1%).

- Tensile Test: Verify teeth strength (≥80N/tooth) under simulated usage conditions.

- Durability Test: Perform 5,000+ open/close cycles to ensure coating integrity and slider smoothness.

- Packaging & Environmental Compliance:

- Use moisture-proof vacuum packaging to protect coatings from humidity.

Technical Advantages:

-

- Lightweight Design: 30%-50% lighter than metal zippers.

- Full Sealing: IPX6-rated water-tightness (dust/waterproof).

- Customization: Color, length, and tensile strength tailored to client needs.

Applications:

-

-

Bags: Waterproof bags, hiking packs, cycling packs—requiring protection from splashes and rain ingress.

-

Garments: Shell jackets, ski wear, down jackets, sun-protective wear, fishing pants—to keep the wearer dry and comfortable.

-

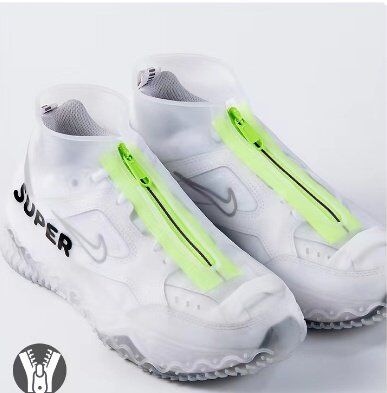

Footwear Decoration: As design elements in waterproof, work, and athletic shoes—combining aesthetics with functional sealing.

-

Tent Systems: Outdoor tents and rapid-assembly large tents—used in waterproof zipper assemblies.

-

Gloves: Ski gloves and waterproof gloves—providing sealed interfaces to block water ingress.

✅ Watertight Zipper Dynamic Test Description

Test Name:

Watertight Zipper Dynamic Test

Objective:

To verify the waterproof performance of the zipper under repeated bending, motion, and mechanical stress — simulating real-world conditions where gear is constantly moving and exposed to water.

Test Procedure Overview:

-

The zipper is mounted on a flexible base that performs cyclic bending movements;

-

During movement, water is sprayed or pressure is applied directly to the zipper;

-

Any sign of leakage is observed under dynamic conditions;

-

The test evaluates sealing performance, mechanical durability, and material bonding under stress.

Key Performance Indicators:

-

💧 Dynamic Waterproof Sealing: Maintains watertightness even when bent, stretched, or in motion;

-

🔁 Durability in Repeated Use: Waterproof performance remains stable through frequent bending and operation cycles;

-

⚙️ Structural Adhesion Strength: Zipper-to-fabric bonding remains intact even under mechanical motion and pressure.

Recommended Applications:

Ideal for dry bags, wetsuits, outdoor jackets, waterproof backpacks, and military-grade waterproof gear.

-

-

Product Details:

Spiral Water-Tight Zipper For Hiking Packs

Benefits of Spiral Water-Tight Zippers for Outdoor Use

Leak-Proof Zipper Technology for Hiking Packs

Custom Spiral Water-Tight Zippers from YGZIP®

Spiral water-tight zippers are high-sealing zippers widely used in waterproof and water-tight clothing and equipment.

1. Product Structure

-

Tape: Made from high-strength nylon or polyester spiral coil structure, offering flexibility, durability, and abrasion resistance — commonly used in outdoor gear and rugged equipment

-

Coil Teeth: Spiral-shaped coil teeth integrated into the tape to form a coil zipper structure, facilitating sealing treatments

-

Sealing Layer: Coated with TPU or PU film on the tape’s surface or back side to enhance water resistance and waterproofing

-

Slider & Stops: Equipped with metal or plastic sliders and top/bottom stops to ensure precise closure and smooth operation.

2. Classification

-

S40 / S60 / S80: Correspond to different tooth sizes and tape widths (#4/#6/#8) tailored for distinct product applications.

-

By Functionality:

-

Standard Waterproof Type: Surface-coated tapes for water-resistant performance—ideal for splash protection.

-

Advanced Airtight/Waterproof Type: Featuring inner seal bridges or multi-layer coatings to deliver superior sealing performance—similar to YKK AQUASEAL® series.

-

3. Application Fields

-

Bags: Waterproof bags, hiking packs, cycling packs—requiring protection from splashes and rain ingress.

-

Garments: Shell jackets, ski wear, down jackets, sun-protective wear, fishing pants—to keep the wearer dry and comfortable.

-

Footwear Decoration: As design elements in waterproof, work, and athletic shoes—combining aesthetics with functional sealing.

-

Tent Systems: Outdoor tents and rapid-assembly large tents—used in waterproof zipper assemblies.

-

Gloves: Ski gloves and waterproof gloves—providing sealed interfaces to block water ingress.

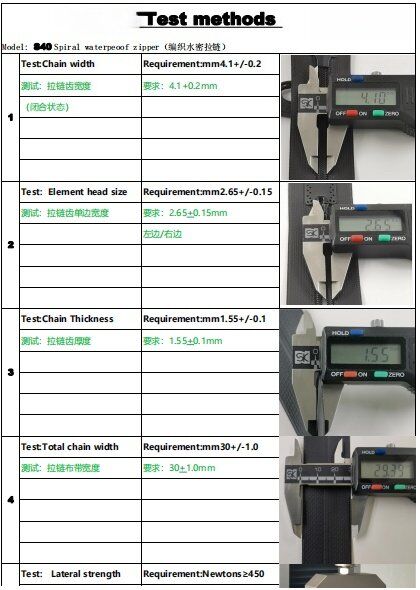

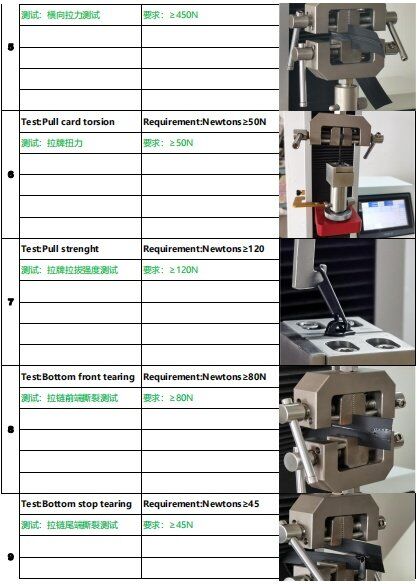

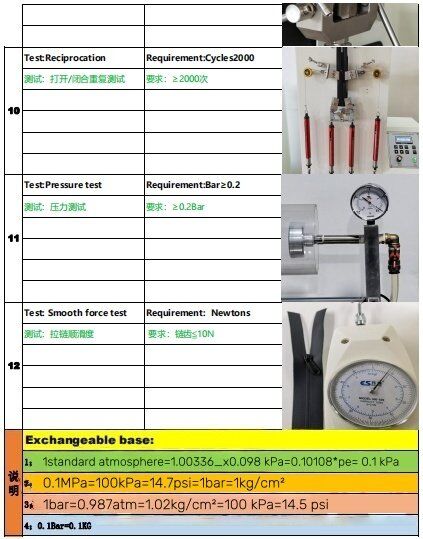

4. Water-tightness Testing & Quality Control

- Airtight Test: Mount the zipper on a test mold, inject compressed air (e.g., 0.5-1.0 bar), and measure leakage rate (≤0.1%).

- Tensile Test: Verify teeth strength (≥80N/tooth) under simulated usage conditions.

- Durability Test: Perform 5,000+ open/close cycles to ensure coating integrity and slider smoothness.

5. Comparison with Standard Water-Resistan Zippers

| Feature | Spiral Waterproof Zipper | Standard Water‑Resistant Coil Zipper |

|---|---|---|

| Structure | Spiral coil teeth + TPU/PU sealing film; can be airtight | Standard coil teeth + DWR or simple film coating; generally only splash‑proof |

| Sealing Performance | Can withstand moderate to high water pressure; suitable for dry bags/sealed pouches | Only resists rain or splash; cannot fully prevent water ingress |

| Use Cases | High‑sealing applications in waterproof bags, airtight compartments, etc. | Everyday outdoor wear, bags, shoes with basic splash resistance |

| Operation Feel | Smooth sliding; lubrication at teeth enhances lifespan | Similar to standard zipper; lightweight but lacks high sealing |

| Durability | TPU/PU films add UV resistance and aging resistance; ideal for long-term outdoor use | Coatings may wear or peel off over time, losing effectiveness |

6. Usage Notes

-

Apply dedicated zipper lubricant at the coil teeth and top stop to improve smoothness and lifespan.

-

When heat-sealing or attaching zipper to fabric, insert release sheets between fabric layers to prevent color bleeding or fabric distortion under temperature and pressure.

Get a Quote ?

or whatsapp for chatting ?

or Request Samples ?

or Explore Collection ?

or Register Our Newsletter for Getting More Zippers With Exclusive Tips And Insights ?

ACTION NOW !

What are common zippers used for?

Common zippers are widely used in clothing, bags, and general-purpose textile products due to their reliability and cost-effectiveness.

Does YGZIP offer size customization for common zippers?

Yes, we provide customizable sizes, materials, and colors to meet your production needs.

What makes a zipper high-end?

High-end zippers use refined materials, smooth operation, and elegant finishes suited for premium fashion designs.

Can I customize the zipper pull for fashion zippers?

Absolutely. YGZIP offers customized pullers with logos, colors, and finishes tailored to your brand.

What are air-tight zippers used for?

Air-tight zippers are used in products requiring sealed enclosures such as diving suits, inflatable tents, and protective gear.

Do air-tight zippers resist water as well?

Yes, air-tight zippers from YGZIP are designed to resist both air and water leakage.

Where are explosion-proof zippers used?

They are commonly used in protective clothing, mining gear, and environments with high safety requirements.

Are these zippers certified?

Yes, YGZIP provides explosion-proof zippers that comply with relevant industrial safety standards.

What is a flame-retardant zipper?

It’s a zipper treated or constructed with materials that resist ignition and slow flame spread, used in fire-protective clothing.

Does YGZIP offer certifications for these zippers?

Yes, all our flame-retardant zippers are tested and meet NFPA, EN, or UL standards.

What is the difference between water-repellent and waterproof zippers?

Water-repellent zippers resist moisture but are not completely watertight, while waterproof zippers provide a full seal.

What applications are these zippers suitable for?

Ideal for rainwear, backpacks, and any product needing light moisture protection.

Can I request custom lengths or colors?

Yes, we offer full customization upon request.

Do you work with fashion designers?

Yes, we collaborate with many international design houses.

What are flame-retardant zippers made of?

Specialized aramid or fire-resistant tapes with heat-treated coatings.

Are flame-retardant zippers customizable?

Yes, we offer various sizes, teeth types, and tape colors.

Can I add a logo on the zipper?

Yes, we provide branding options for sliders and pullers.

What materials are used in YGZIP's metal zippers?

YGZIP metal zippers are crafted from high-quality brass, aluminum, or nickel, ensuring durability and corrosion resistance.

Are these metal zippers suitable for heavy-duty use?

Absolutely. YGZIP metal zippers are designed for high strength and are ideal for jeans, leather bags, jackets, and other demanding applications.