Spiral Air-Tight Zipper for Waterproof Bags | YGZIP® Leak-Proof Zipper Solutions

Spiral airtight zippers are high-sealing zippers widely used in waterproof and airtight clothing and equipment.

Additional information

| Slider | |

|---|---|

| Feature | |

| Size | S40, S60, S80 |

| Color | Black, Customized pantone color, White |

| Material | |

| Application |

The manufacturing process of the product

Production Process of Spiral Airtight Zipper

- Raw Material Preparation:

- Select high-strength nylon 6 or nylon 66 yarn for abrasion resistance and tensile strength.

- Prepare TPU (thermoplastic polyurethane) or rubber-based waterproof coatings for airtight sealing.

- Auxiliary materials: Metal/plastic sliders, top/bottom stops, and polyester tape substrate.

- Nylon Braiding Process:

- Braid nylon yarn into continuous zipper teeth strips using high-speed braiding machines, controlling tooth spacing and density.

- Stabilize the shape through high-temperature heat pressing to prevent deformation.

- Coating and Sealing Treatment:

- Apply TPU or rubber coating evenly on the braided nylon tape to fill gaps between teeth.

- Cure the coating via UV or hot-air drying to form a seamless airtight layer.

- For premium products, add sealing strips at the tooth base for enhanced airtightness.

- Tape and Slider Assembly:

- Stitch the coated nylon braided teeth to polyester substrate tape for strength and flexibility.

- Assemble sliders with precision machinery to ensure smooth operation.

- Attach waterproof metal/plastic top/bottom stops to secure the slider.

- Airtightness Testing & Quality Control:

- Airtight Test: Mount the zipper on a test mold, inject compressed air (e.g., 0.5-1.0 bar), and measure leakage rate (≤0.1%).

- Tensile Test: Verify teeth strength (≥80N/tooth) under simulated usage conditions.

- Durability Test: Perform 5,000+ open/close cycles to ensure coating integrity and slider smoothness.

- Packaging & Environmental Compliance:

- Use moisture-proof vacuum packaging to protect coatings from humidity.

Technical Advantages:

-

- Lightweight Design: 30%-50% lighter than metal zippers.

- Full Sealing: IP67-rated airtightness (dust/waterproof).

- Customization: Color, length, and tensile strength tailored to client needs.

Applications:

-

- Outdoor Gear: Inflatable tents, wetsuits, hiking backpacks.

- Medical Devices: Sterile protective suits, isolation chambers.

- Industrial Protection: Chemical-resistant suits, airtight packaging.

Product Details:

Spiral Air-Tight Zipper for Waterproof Bags

Benefits of Spiral Air-Tight Zippers for Outdoor Use

Leak-Proof Zipper Technology for Waterproof Bags

Custom Spiral Air-Tight Zippers from YGZIP®

Spiral airtight zippers are high-sealing zippers widely used in waterproof and airtight clothing and equipment.

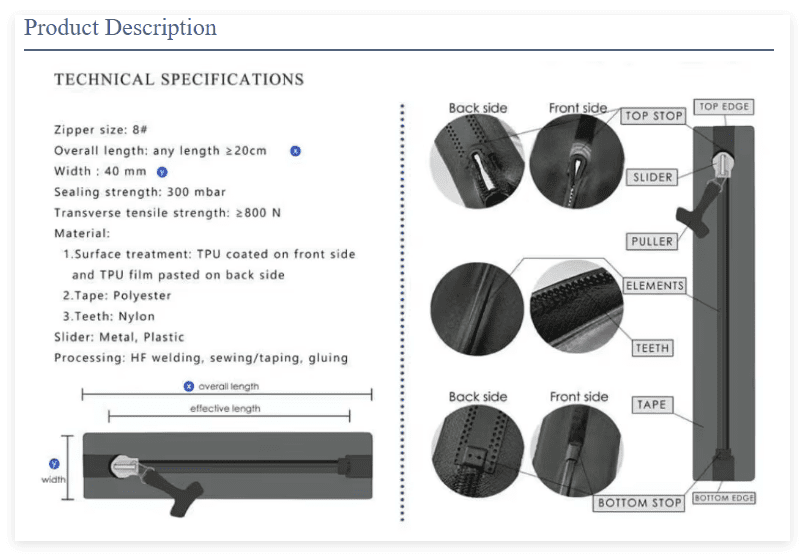

The core structure of nylon-woven airtight zippers includes:

- Teeth: Made of high-strength nylon (e.g., PA6 or PA66) through a woven process, forming a continuous spiral or dual-spiral structure for flexibility and tear resistance.

- Coating: Teeth are coated with polyurethane (PU) or thermoplastic polyurethane (TPU) to enhance airtightness.

- Slider: Designed with fully or semi-enclosed structures; high-end models may include built-in sealing strips.

- Tape: Nylon fabric is bonded to teeth via high-temperature pressing, with edges sealed by ultrasonic welding or adhesive.

Classified by function and structure:

- Standard Airtight Zippers: For general sealing (e.g., tents, inflatable products).

- High-Pressure Airtight Zippers: Designed for environments with pressure differentials (e.g., aerospace, diving gear).

- Customized Zippers: Tailored for specific widths, lengths, or colors (e.g., medical suits, industrial equipment).

Airtightness Testing & Quality Control

- Airtight Test: Mount the zipper on a test mold, inject compressed air (e.g., 0.5-1.0 bar), and measure leakage rate (≤0.1%).

- Tensile Test: Verify teeth strength (≥80N/tooth) under simulated usage conditions.

- Durability Test: Perform 5,000+ open/close cycles to ensure coating integrity and slider smoothness.

Application:

- Outdoor Gear: Inflatable tents, wetsuits, hiking backpacks.

- Medical Protection: Airtight isolation suits, sterile packaging.

- Industrial Equipment: Gas pipeline seals, dust covers.

- Aerospace: Spacesuits, cabin pressure systems.

Airtight Zippers vs. Waterproof Zippers

| Feature | Airtight Zippers | Waterproof Zippers |

|---|---|---|

| Core Function | Block gas (air, dust) | Block liquid (water, oil) |

| Material | Nylon + PU/TPU + sealed slider | Polyester/PVC + waterproof tape |

| Test Standard | ASTM D737 | IPX7/IPX8 |

| Application | High-pressure, sterile spaces | Raincoats, water sports |

| Cost | Higher (precision coating) | Moderate |

Pros & Cons:

- Airtight: Superior in high-pressure environments but less flexible.

- Waterproof: Cost-effective and lightweight but fails in gas blocking.

Get a Quote ?

or whatsapp for chatting ?

or Request Samples ?

or Explore Collection ?

or Register Our Newsletter for Getting More Zippers With Exclusive Tips And Insights ?

ACTION NOW !

What are common zippers used for?

Common zippers are widely used in clothing, bags, and general-purpose textile products due to their reliability and cost-effectiveness.

Does YGZIP offer size customization for common zippers?

Yes, we provide customizable sizes, materials, and colors to meet your production needs.

What makes a zipper high-end?

High-end zippers use refined materials, smooth operation, and elegant finishes suited for premium fashion designs.

Can I customize the zipper pull for fashion zippers?

Absolutely. YGZIP offers customized pullers with logos, colors, and finishes tailored to your brand.

What are air-tight zippers used for?

Air-tight zippers are used in products requiring sealed enclosures such as diving suits, inflatable tents, and protective gear.

Do air-tight zippers resist water as well?

Yes, air-tight zippers from YGZIP are designed to resist both air and water leakage.

Where are explosion-proof zippers used?

They are commonly used in protective clothing, mining gear, and environments with high safety requirements.

Are these zippers certified?

Yes, YGZIP provides explosion-proof zippers that comply with relevant industrial safety standards.

What is a flame-retardant zipper?

It’s a zipper treated or constructed with materials that resist ignition and slow flame spread, used in fire-protective clothing.

Does YGZIP offer certifications for these zippers?

Yes, all our flame-retardant zippers are tested and meet NFPA, EN, or UL standards.

What is the difference between water-repellent and waterproof zippers?

Water-repellent zippers resist moisture but are not completely watertight, while waterproof zippers provide a full seal.

What applications are these zippers suitable for?

Ideal for rainwear, backpacks, and any product needing light moisture protection.

Can I request custom lengths or colors?

Yes, we offer full customization upon request.

Do you work with fashion designers?

Yes, we collaborate with many international design houses.

What are flame-retardant zippers made of?

Specialized aramid or fire-resistant tapes with heat-treated coatings.

Are flame-retardant zippers customizable?

Yes, we offer various sizes, teeth types, and tape colors.

Can I add a logo on the zipper?

Yes, we provide branding options for sliders and pullers.

What materials are used in YGZIP's metal zippers?

YGZIP metal zippers are crafted from high-quality brass, aluminum, or nickel, ensuring durability and corrosion resistance.

Are these metal zippers suitable for heavy-duty use?

Absolutely. YGZIP metal zippers are designed for high strength and are ideal for jeans, leather bags, jackets, and other demanding applications.