Nylon Flame-Retardant Zipper for Beddings | Fire-Resistant & Durable | YGZIP®

YG nylon fire-retardant zippers are crafted with 100% aramid material, offering exceptional durability, anti-aging properties, and permanent flame resistance. Designed to withstand temperatures of up to 180°C without deforming, these zippers remain structurally intact and exhibit zero melting or dripping under intense heat. Even in the most challenging environments, our zippers extinguish flames within 2 seconds of removal from fire and retain full functionality post-burn.

Additional information

| Size | #10, #3, #5, #8 |

|---|---|

| Material | |

| Color | Black, Customized pantone color, White |

| Length | |

| Feature | |

| Slider | |

| Application | |

| Item | metal, nylon, plastic |

The manufacturing process of the product

Production Process of Fire-Resistant Zippers

Fire-resistant zippers are primarily used in fire-resistant clothing, firefighting equipment, and other fields, offering high-temperature resistance and flame-retardant properties. The production process of fire-resistant zippers is as follows:

- Material Preparation

The main materials for fire-resistant zippers include flame-retardant nylon, flame-retardant polyester, and flame-retardant zipper sliders and teeth.

- Zipper Teeth Production

Injection molding technology is used to process flame-retardant materials into zipper teeth, ensuring the zipper’s high-temperature resistance and strength.

- Tape Manufacturing

Flame-retardant fibers are woven into tapes using weaving machines. The types of tapes include flat tapes and ribbed tapes.

- Zipper Assembly

The tapes are sewn together with the zipper teeth using high-precision machinery to ensure tight integration and prevent issues such as jamming or breakage.

- Fire-Resistant Treatment

The zippers undergo fire-resistant treatment to enhance their high-temperature resistance and flame-retardant properties, ensuring they function properly in high-temperature environments.

- Quality Control

Each fire-resistant zipper undergoes strict quality control tests, including high-temperature resistance tests, tensile strength tests, and flame-retardant performance evaluations, ensuring their reliability under extreme conditions.

- Packaging

The zippers that pass the tests are packaged according to customer requirements and prepared for shipment.

Through this process, we ensure that each fire-resistant zipper meets the highest standards of quality and performance, catering to the diverse needs of our clients.

Get a Quote ?

or Contact Us Today ?

or whatsapp for chatting ?

or Request Samples ?

or Explore Collection ?

or Register Our Newsletter for Getting More Zippers With Exclusive Tips And Insights ?

ACTION NOW !

Product Details:

Nylon Flame-Retardant Zippers for Beddings

Fire-Resistant Zippers for Mattresses and Home Textiles

Benefits of Nylon Flame-Retardant Zippers for Bedding Safety

Custom Flame-Retardant Zipper Solutions from YGZIP®

YG Fire-Retardant Zippers: Built to Endure, Engineered for Safety

Unmatched Performance in Extreme Conditions

Innovative Design for Ultimate Reliability

Every YG zipper is a testament to resilience and innovation. Our zippers are engineered for industrial-grade thermal protection, fully meeting the NFPA 2112-2023 standard. During rigorous testing, YG nylon flam retardant zippers maintained integrity and operability after enduring 180°C heat for 5 minutes, making them ideal for high-risk industries.YG fire-retardant zippers are crafted with 100% aramid material, offering exceptional durability, anti-aging properties, and permanent flame resistance. Designed to withstand temperatures of up to 180°C without deforming, these zippers remain structurally intact and exhibit zero melting or dripping under intense heat. Even in the most challenging environments, our zippers extinguish flames within 2 seconds of removal from fire and retain full functionality post-burn.

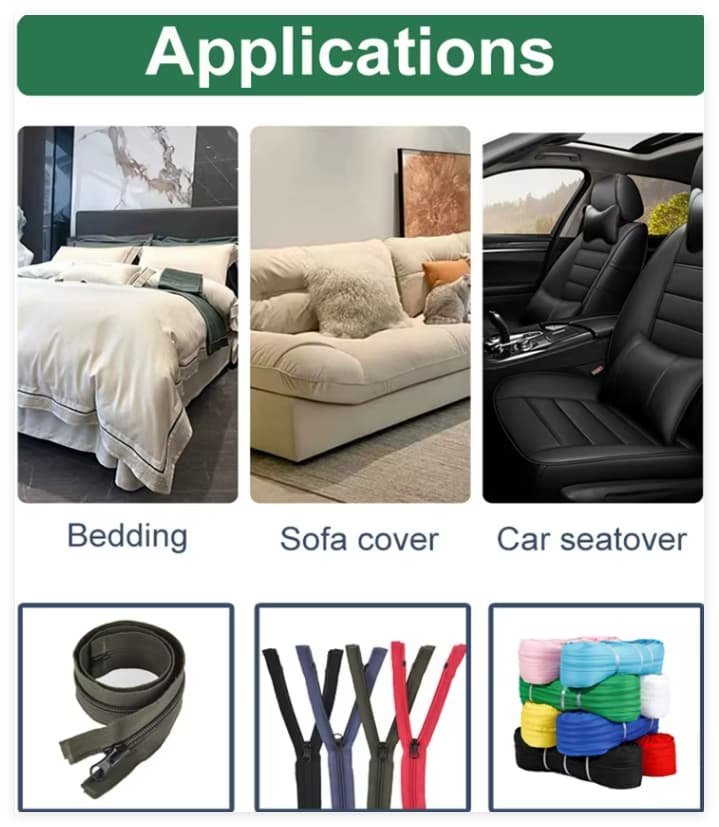

Applications Across Critical Industries

YG fire-retardant zippers are widely used in:

- Firefighter suits

- Petroleum workwear

- Aerospace uniforms

Technology That Sets Us Apart

Through years of dedicated research and development, we have mastered the core technologies of fire-retardant zippers.

- Advanced production techniques ensure precision manufacturing.

- State-of-the-art testing equipment guarantees unparalleled safety.

- Strict quality control from raw material selection to finished products ensures superior performance.

Attention to Every Detail

From the choice of premium materials to meticulous production processes, every zipper undergoes multiple rounds of testing to meet the highest standards. Our dedication to excellence means that each YG zipper is built to exceed expectations, ensuring reliability in even the toughest environments.

Your Trusted Partner in Safety

At YG, we believe that a great zipper should endure any challenge. With our relentless commitment to innovation and customer satisfaction, we continue to deliver products that protect, perform, and inspire confidence.

Choose YG fire-retardant zippers — where safety meets durability.

What are common zippers used for?

Common zippers are widely used in clothing, bags, and general-purpose textile products due to their reliability and cost-effectiveness.

Does YGZIP offer size customization for common zippers?

Yes, we provide customizable sizes, materials, and colors to meet your production needs.

What makes a zipper high-end?

High-end zippers use refined materials, smooth operation, and elegant finishes suited for premium fashion designs.

Can I customize the zipper pull for fashion zippers?

Absolutely. YGZIP offers customized pullers with logos, colors, and finishes tailored to your brand.

What are air-tight zippers used for?

Air-tight zippers are used in products requiring sealed enclosures such as diving suits, inflatable tents, and protective gear.

Do air-tight zippers resist water as well?

Yes, air-tight zippers from YGZIP are designed to resist both air and water leakage.

Where are explosion-proof zippers used?

They are commonly used in protective clothing, mining gear, and environments with high safety requirements.

Are these zippers certified?

Yes, YGZIP provides explosion-proof zippers that comply with relevant industrial safety standards.

What is a flame-retardant zipper?

It’s a zipper treated or constructed with materials that resist ignition and slow flame spread, used in fire-protective clothing.

Does YGZIP offer certifications for these zippers?

Yes, all our flame-retardant zippers are tested and meet NFPA, EN, or UL standards.

What is the difference between water-repellent and waterproof zippers?

Water-repellent zippers resist moisture but are not completely watertight, while waterproof zippers provide a full seal.

What applications are these zippers suitable for?

Ideal for rainwear, backpacks, and any product needing light moisture protection.

Can I request custom lengths or colors?

Yes, we offer full customization upon request.

Do you work with fashion designers?

Yes, we collaborate with many international design houses.

What are flame-retardant zippers made of?

Specialized aramid or fire-resistant tapes with heat-treated coatings.

Are flame-retardant zippers customizable?

Yes, we offer various sizes, teeth types, and tape colors.

Can I add a logo on the zipper?

Yes, we provide branding options for sliders and pullers.

What materials are used in YGZIP's metal zippers?

YGZIP metal zippers are crafted from high-quality brass, aluminum, or nickel, ensuring durability and corrosion resistance.

Are these metal zippers suitable for heavy-duty use?

Absolutely. YGZIP metal zippers are designed for high strength and are ideal for jeans, leather bags, jackets, and other demanding applications.