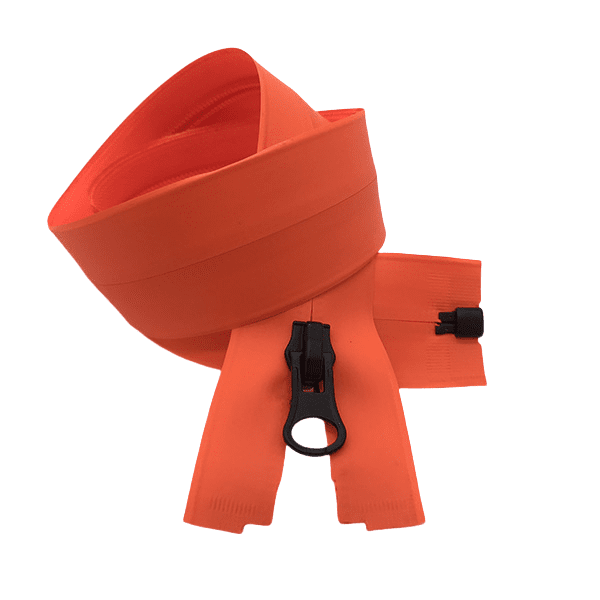

Colored Water-Repellent Zipper for Garments

Colored matte zippers are NEW GENERATION water repellent zippers and cost-effective entrance solutions.

Coating with PU colored film, NO White scratches and MORE Accurate Color, Sharper and Brighter color comparing to common water repellent zipper you could find in the market.

Colors can be customized, just advise us pantone color no, or ykk color no. or Chinese GCC color card no.all we can make for you.

Additional information

| Size | #10, #3, #5, #8 |

|---|---|

| Material | |

| Color | Black, Customized pantone color, White |

| Length | |

| Feature | CE, chain roll, OE, T/W |

| Slider | Auto lock slider, customized logo puller, Double sizes slider, high-strength plastic, Non lock slider, Semi lock slider |

| Application |

The manufacturing process of the product

Production Process of Nylon Waterproof Zippers

Nylon waterproof zippers are widely used in outdoor equipment, rain gear, wetsuits, and other fields due to their excellent waterproof performance and durability. The production process of nylon waterproof zippers is as follows:

1. Material Preparation

The main materials include nylon tapes and waterproof coating materials. Nylon tapes are usually made from high-strength nylon fibers to ensure the zipper’s durability and tensile strength. Waterproof coating materials such as PVC, TPU films, or waterproof agents are used to impart waterproof functionality to the zippers.

2. Tape Manufacturing

Nylon fibers are woven into tapes using weaving machines. The types of tapes include flat tapes and ribbed tapes. Flat tapes are used for nylon zippers, while ribbed tapes (with a core line integrated into the tape) are used for resin or metal zippers.

3. Waterproof Treatment

The tapes undergo waterproof treatment, commonly through:

• Lamination: Attaching waterproof films (such as PVC or TPU films) to the tape surface.

• Coating: Applying waterproof coatings to the tape surface.

• Impregnation: Soaking the tapes in waterproof agents to allow penetration into the tape.

4. Zipper Teeth Formation

The materials are processed into zipper teeth. For nylon zippers, nylon monofilaments are heated, toothed, and wound around a center line to form the teeth.

5. Zipper Assembly

The waterproof-treated tapes and zipper teeth are sewn together using sewing machines to form complete zippers.

6. Pre-finishing

The assembled zippers undergo pre-finishing treatments, including heat pre-shrinking and oil removal, to ensure stable specifications and improved dyeing effects.

7. Dyeing

The zippers are dyed according to customer requirements to ensure uniform and vibrant colors.

8. Ironing

The dyed zippers are ironed to ensure they are flat and ready for subsequent use.

9. Packaging

The finished zippers are packaged according to customer specifications and prepared for shipment.

Through this process, we ensure that each nylon waterproof zipper meets the highest standards of quality and performance, catering to the diverse needs of our clients.

Product Details:

Colored Water-Repellent Zipper for Garments

Waterproof and Stylish Zippers for Jackets and Sportswear

Key Features of Colored Water-Repellent Zippers

Why Choose YGZIP®

Colored matte zippers are NEW GENERATION water repellent zippers and cost-effective entrance solutions.

Coating with PU colored film, NO White scratches and MORE Accurate Color, Sharper and Brighter color comparing to common water repellent zipper you could find in the market.

Colors can be customized, just advise us pantone color no, or ykk color no. or Chinese GCC color card no.all we can make for you.

Additionally, it boasts exceptional durability, withstanding high temperatures without compromising its integrity. The zipper’s soft and smooth texture ensures a comfortable feel, while its precise craftsmanship results in a tight and seamless closure, providing enhanced protection against water splashes and moisture.

Zipper Features:

- Flexibility: It is softer compared to regular waterproof zippers.

- Cold Resistance: Capable of withstanding temperatures as low as -40°C without stiffening.

- Heat Resistance: Endures temperatures up to 160°C, making it suitable for seamless heat pressing.

- Wear Resistance: Exhibits excellent abrasion resistance, tested for over 1000 double strokes.

- Washing Resistance: Can withstand over 20 washes at 60°C.

- Boiling Test Passed: Successfully passes a one-hour boiling test at 100°C.

- Flat & Smooth Surface: The surface is smoother than standard waterproof zippers, without visible lines.

- Tight Slit: Seam is tighter than regular waterproof zippers, enhancing waterproof performance.

- Acetone Solvent Resistance: Withstands a 1-minute acetone immersion test, proving resistance to dry cleaning solvents.

We’re confident that our products will be a game-changer in the market, offering superior performance and sustainability compared to conventional options.

If you’re interested in learning more about our environmentally friendly waterproof zipper, including pricing details or samples for evaluation, please don’t hesitate to reach out. We’re here to assist you every step of the way and ensure that your experience with us exceeds your expectations.

Get a Quote ?

or Explore Custom Options ?

or whatsapp for chatting ?

or Request Samples ?

or Explore Collection ?

or Register Our Newsletter for Getting More Zippers With Exclusive Tips And Insights ?

ACTION NOW !

What are common zippers used for?

Common zippers are widely used in clothing, bags, and general-purpose textile products due to their reliability and cost-effectiveness.

Does YGZIP offer size customization for common zippers?

Yes, we provide customizable sizes, materials, and colors to meet your production needs.

What makes a zipper high-end?

High-end zippers use refined materials, smooth operation, and elegant finishes suited for premium fashion designs.

Can I customize the zipper pull for fashion zippers?

Absolutely. YGZIP offers customized pullers with logos, colors, and finishes tailored to your brand.

What are air-tight zippers used for?

Air-tight zippers are used in products requiring sealed enclosures such as diving suits, inflatable tents, and protective gear.

Do air-tight zippers resist water as well?

Yes, air-tight zippers from YGZIP are designed to resist both air and water leakage.

Where are explosion-proof zippers used?

They are commonly used in protective clothing, mining gear, and environments with high safety requirements.

Are these zippers certified?

Yes, YGZIP provides explosion-proof zippers that comply with relevant industrial safety standards.

What is a flame-retardant zipper?

It’s a zipper treated or constructed with materials that resist ignition and slow flame spread, used in fire-protective clothing.

Does YGZIP offer certifications for these zippers?

Yes, all our flame-retardant zippers are tested and meet NFPA, EN, or UL standards.

What is the difference between water-repellent and waterproof zippers?

Water-repellent zippers resist moisture but are not completely watertight, while waterproof zippers provide a full seal.

What applications are these zippers suitable for?

Ideal for rainwear, backpacks, and any product needing light moisture protection.

Can I request custom lengths or colors?

Yes, we offer full customization upon request.

Do you work with fashion designers?

Yes, we collaborate with many international design houses.

What are flame-retardant zippers made of?

Specialized aramid or fire-resistant tapes with heat-treated coatings.

Are flame-retardant zippers customizable?

Yes, we offer various sizes, teeth types, and tape colors.

Can I add a logo on the zipper?

Yes, we provide branding options for sliders and pullers.

What materials are used in YGZIP's metal zippers?

YGZIP metal zippers are crafted from high-quality brass, aluminum, or nickel, ensuring durability and corrosion resistance.

Are these metal zippers suitable for heavy-duty use?

Absolutely. YGZIP metal zippers are designed for high strength and are ideal for jeans, leather bags, jackets, and other demanding applications.