Engineered to prevent zipper bursting under compression, overpacking, and extreme travel handling.

YGZIP’s Double-Layer Explosion-Proof Zipper is designed for luggage brands that require higher load-bearing performance, improved durability, and reduced warranty risk.

Engineered to prevent zipper bursting under compression, overpacking, and extreme travel handling.

YGZIP’s Double-Layer Explosion-Proof Zipper is designed for luggage brands that require higher load-bearing performance, improved durability, and reduced warranty risk.

Why Standard Luggage Zippers Fail

Traditional single-layer zipper systems often suffer from:

-

Chain separation under internal pressure

-

Tape tearing at stitching lines

-

Slider deformation under heavy load

-

Increased return and repair rates

As luggage sizes increase and airline handling becomes more aggressive, zipper reinforcement becomes essential.

Our Engineering Solution

YGZIP Double-Layer Explosion-Proof Zipper features:

✔ Dual-layer structural teeth construction

✔ High-density polyester weaving

✔ Anti-separation coil / molded teeth geometry

✔ Heavy-duty zinc alloy die-cast slider

✔ Optimized load distribution system

✔ Burst resistance performance testing

This system significantly improves structural reliability in high-load applications.

Technical Specifications

| Item | Specification |

|---|---|

| Zipper Type | Coil |

| Sizes Available | #5 / #8 / #10 |

| Tape Material | High-Tensile Polyester |

| Reinforcement | Dual-Layer Structural Teeth |

| Slider | Zinc Alloy Die-Cast |

| Surface Finish | Nickel / Black / Custom |

| Customization | Logo Puller / Color Matching |

| Application | Luggage, Travel Bags, Tactical Gear |

Custom strength specifications available upon request.

🔍 Comparison Module

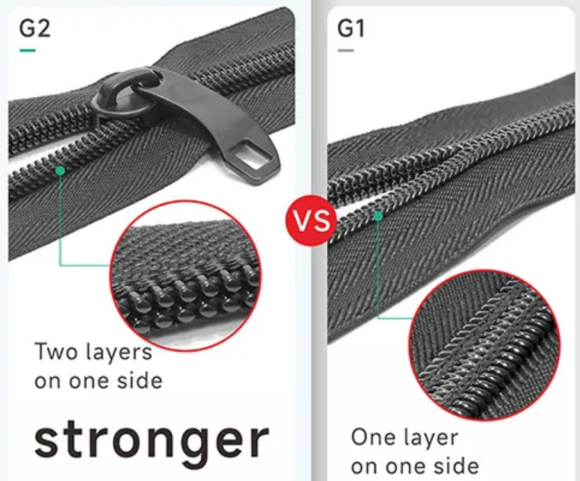

Standard Zipper vs Double-Layer Explosion-Proof Zipper

Structural Comparison

Standard Zipper vs Double-Layer Explosion-Proof Zipper

When selecting zipper systems for luggage and travel applications, structural design determines long-term durability and warranty risk.

Below is a professional comparison:

| Feature | Standard Single-Layer Zipper | Double-Layer Explosion-Proof Zipper |

|---|---|---|

| Teeth Structure | Single teeth | Dual-layer reinforced structural teeth |

| Load Distribution | Concentrated stress | Evenly distributed structural load |

| Burst Resistance | Moderate | High burst resistance under compression |

| Chain Separation Risk | Higher under overpacking | Significantly reduced |

| Slider Type | Standard zinc slider | Reinforced die-cast heavy-duty slider |

| Durability Cycle | Basic commercial level | Engineered for heavy-duty travel |

| Warranty Risk | Higher in large luggage | Reduced failure rate |

| Brand Positioning | Entry to mid-level | Premium / high-durability positioning |

| Suitable For | Light bags | Luggage, heavy-duty travel gea |

💰 Cost vs Warranty Risk Visualization Module

Cost vs Warranty Risk Analysis

Why Reinforced Zippers Reduce Total Product Cost

At first glance, double-layer reinforced zippers may appear slightly more expensive than standard zipper systems.

However, total product cost is not determined by component price —

it is determined by failure rate and warranty exposure.

Cost Structure Comparison (Illustrative Model)

| Item | Standard Zipper | Double-Layer Reinforced Zipper |

|---|---|---|

| Unit Zipper Cost | Lower | Slightly Higher |

| Estimated Failure Rate | 3% – 8% (Large Luggage) | <1% (Heavy-Duty Application) |

| Warranty Repair Cost | High | Significantly Reduced |

| Retail Return Risk | Moderate to High | Low |

| Brand Reputation Risk | Medium | Low |

| Total Long-Term Cost | Higher | Lower |

Visual Cost Logic

Imagine 10,000 luggage units produced:

Standard Zipper Scenario

-

5% failure rate

-

500 warranty claims

-

Average handling cost per claim: $18–$35

-

Estimated loss: $9,000 – $17,500

Reinforced Zipper Scenario

-

<1% failure rate

-

100 claims or fewer

-

Estimated loss: $1,800 – $3,500

The cost difference in zipper upgrade is often only 1–3% of total product cost.

But warranty exposure can exceed 5–10x that amount.

Structural Investment = Risk Control

Reinforced zipper systems:

✔ Reduce burst failure

✔ Lower after-sales expenses

✔ Protect brand positioning

✔ Improve retailer confidence

✔ Support premium pricing strategy

In luggage manufacturing, the cheapest zipper is rarely the most economical choice.

Performance Advantages

-

Higher burst resistance under compression

-

Improved tensile strength

-

Reduced chain separation risk

-

Better load distribution

-

Enhanced durability in airport handling

-

Lower after-sales repair cost

For premium luggage positioning, structural strength matters.

Applications

-

Hard-shell luggage

-

Soft luggage

-

Carry-on suitcases

-

Travel backpacks

-

Tactical travel bags

-

Heavy-duty expedition gear

Designed for OEM and ODM luggage manufacturers.

Quality Control & Testing

Each production batch undergoes:

-

Tensile strength testing

-

Burst resistance simulation

-

Slider cycling test

-

Tape tear strength verification

-

Dimensional inspection

YGZIP focuses on engineering reliability, not commodity-grade supply.

Why Upgrade?

In high-capacity luggage, internal pressure increases dramatically during overpacking and airport stacking.

Single-layer zipper systems concentrate stress along one tape edge.

Double-layer construction distributes force across two structural layers, significantly improving stability.

The upgrade cost is minimal compared to:

-

Warranty replacements

-

Brand reputation damage

-

Distributor complaints

-

Retail returns

Structural reliability protects brand value.

Make the Economical Decision

If your brand is targeting:

-

Premium durability

-

International distribution

-

Large luggage formats

-

Reduced warranty claims

Upgrading to a double-layer explosion-proof zipper is a structural decision, not a cost increase.

Upgrade Your Luggage Structure Today

If your brand is positioning toward durability, premium performance, or reduced warranty claims, reinforced zipper systems are no longer optional.

📩 Request:

-

Structural samples

-

Technical comparison sheet

-

Burst resistance test data

-

OEM customization support

Let’s build stronger luggage from the inside out.

We help luggage brands reduce failure risk and improve product durability.

Need Custom Explosion Proof Zipper Solutions?

👉 Read Functional Zipper Comparison

👉 Read Waterproof Zippers for Real-World Applications

👉 Read How Airtight Zippers Are Made

YGZIP.COM

Functional Zipper Solutions for Real-World Applications

A double-layer explosion-proof zipper is a reinforced zipper structure featuring dual seam construction that distributes internal pressure and reduces burst failure risk in large or heavy-duty luggage.

Large suitcases generate high internal pressure when overpacked. Double-layer reinforcement distributes stress across two structural layers, reducing seam concentration and improving durability.

Standard zippers rely on a single seam line to bear load, while double-layer reinforced zippers feature dual structural stitching that improves tensile strength and burst resistance.

Yes. Reinforced zipper structures lower failure rates in high-stress luggage systems, reducing after-sales claims and protecting brand reputation.

Explosion-proof zippers are recommended for luggage manufacturers producing large-size suitcases, expandable luggage systems, heavy-duty bags, and premium travel collections.